More is expected today from the owner/operators of pipelines than ever before – and that’s fair. Pipelines have the potential to provide incredible benefits to millions of people, but when there are issues, they can have a huge negative impact. Leaks can damage the environment and leave the pipeline out of commission. For this reason it is vital that a pipeline have systems in place to identify leaks immediately and accurately, in addition they must be able to sense potential problems in order to pre-empt issues before they occur. The 3-D has partnered with Rocktest to supply a proactive solution using distributed fibre optic sensing technology.

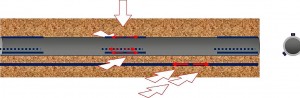

Our solution can either monitor the entire pipeline, or it can be installed as a back up to existing Integrity Management systems at strategic areas such as water crossings and known areas of potential subsidence or soil movement. Using fiber optics, combined with the accuracy of the Smartec sensors, provides Pipeline Integrity Management that the public and the regulators now demand in this country. As the sensors can detect small amounts of cooling in gas pipelines, or small increases in temperatures in crude oil pipelines, micro-leakages can be detected within seconds, and can be identified to an area within 1m. The sensors can also detect issues arising from third party intrusions, tampering or sabotage whether intentional or as a result of an accident from digging too near the pipeline.

Upon identification of anomalies, data is instantly transferred to a graphic user interface, which has the capability to integrate with GIS and SCADA systems. This ability for immediate detection allows for quick initialization of Emergency Response procedures, and ensures field crews can be dispatched to the precise area of concern as soon as possible.

Pipelines are different from other infrastructure. Their length, and distance from the monitoring location to any point of the pipeline could be hundreds of kilometres in length. This demands that the Integrity Management system applied have 21st century solutions. Systems must be able to detect leaks when they are at their smallest and localized. Flying over the pipeline yesterday, or walking the line last week isn’t enough. Areas of exceptional vulnerability or those that are the most environmentally sensitive must be monitored 24/7/365. It is in everyone’s best interest to have a solid, reliable Integrity Management system in place to detect leaks immediately.

More technical details of the leak detection solutions are available here.

To learn more about 3-D Integrity Management go to our website.

3-D is also an industry leader in Line Locating Services. For information on our Line Locating you can go to our website or read our FAQ post.

Follow us on Twitter and LinkedIn and stay up to date with what we are working on and all the latest news in our industry.